Power factor correction (PFC) is essential in industrial plants to improve energy efficiency, reduce electricity costs, and enhance the lifespan of electrical equipment. Industrial facilities often operate with inductive loads such as motors, transformers, and lighting systems, which cause a lagging power factor. A low power factor leads to increased electrical losses, reduced system capacity, and higher utility charges. Various techniques can be employed to correct the power factor and optimize energy consumption.

Understanding Power Factor

Power factor (PF) is the ratio of real power (kW) to apparent power (kVA) in an electrical system. It indicates how effectively electrical power is being converted into useful work. A power factor of 1 (or 100%) means all the power is being effectively used, while a lower power factor signifies wasted energy due to reactive power consumption.

Common Power Factor Correction Methods

Several methods are used to improve power factor in industrial plants:

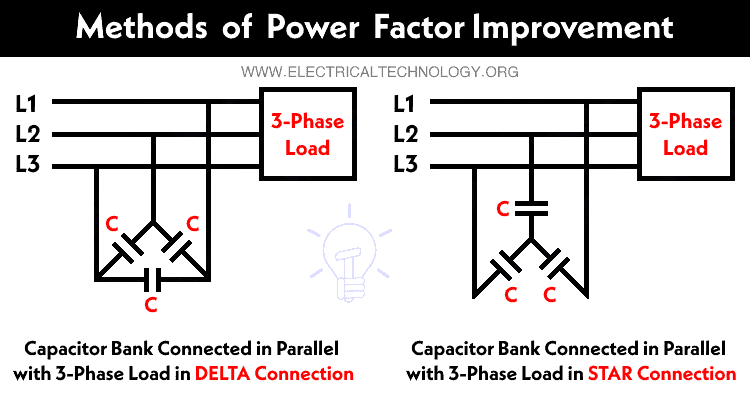

- Capacitor Banks

- Capacitors are installed in parallel with inductive loads to supply reactive power locally, reducing the lagging power factor.

- They can be fixed or switched, depending on load requirements.

- Synchronous Condensers

- These are synchronous motors operating without mechanical loads, providing reactive power by over-exciting their field windings.

- They enhance system stability and improve power factor.

- Automatic Power Factor Correction (APFC) Systems

- APFC systems automatically adjust reactive power supply based on real-time demand.

- They optimize power factor correction dynamically, ensuring efficient operation.

- Phase Advancers

- AC exciters connected to the rotor circuit of induction motors improve the motor’s power factor.

- They are particularly useful for large industrial motors.

- Static VAR Compensators (SVCs)

- SVCs use thyristor-controlled reactors and capacitors to provide continuous reactive power compensation.

- They help maintain a stable power factor under varying load conditions.

- Active Power Filters

- These filters generate current components that cancel out harmonic distortion, improving power factor.

- They are effective in mitigating power quality issues.

- Switched Capacitor Banks

- Automatic switching devices vary reactive power demand based on load requirements.

- They enhance power factor dynamically.

- Static Synchronous Compensator (STATCOM)

- A voltage source converter that provides reactive power compensation, harmonic filtering, and voltage regulation.

- It is highly effective in industrial applications.

Benefits of Power Factor Correction

Implementing PFC techniques in industrial plants offers several advantages:

- Reduced Electricity Costs: Utilities often impose penalties for low power factor, and correction helps avoid these charges.

- Improved System Efficiency: Lower reactive power demand reduces losses in conductors and transformers.

- Enhanced Equipment Lifespan: Reduced current flow minimizes heating and premature aging of electrical components.

- Optimized Energy Consumption: Efficient power utilization leads to lower operational costs and environmental benefits.

Conclusion

Effective power factor correction is essential for industrial plants to maintain energy efficiency, reduce costs, and enhance system reliability. By implementing appropriate correction techniques, industries can optimize their electrical systems, prevent unnecessary energy wastage, and comply with utility regulations. A well-managed power factor not only improves operational performance but also contributes to sustainable energy practices, making it a vital component of modern industrial management.