Introduction

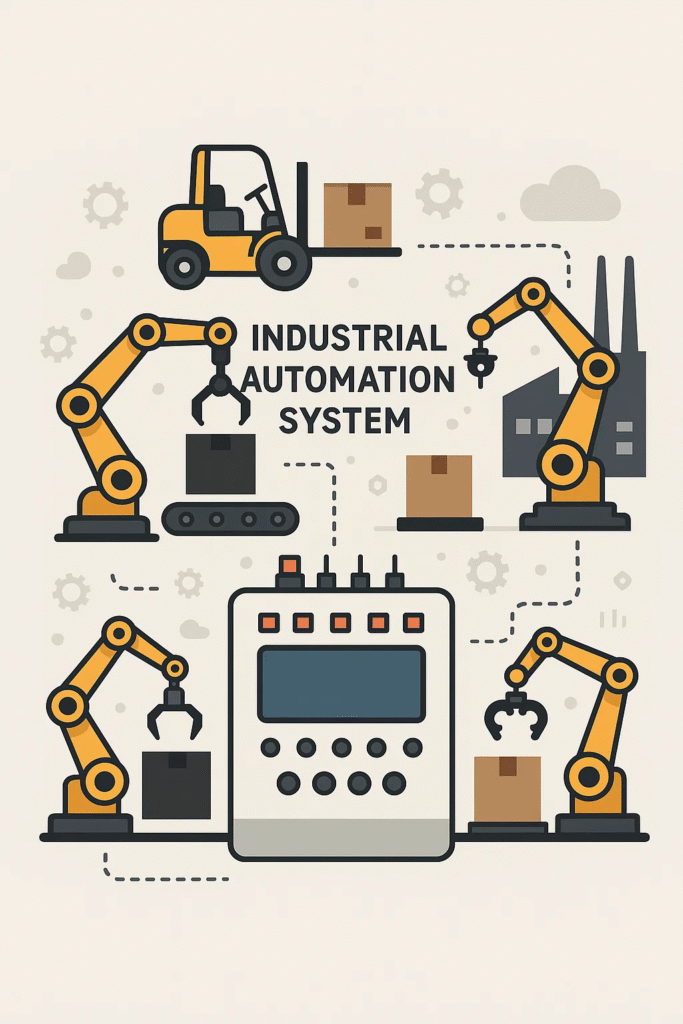

Industrial automation refers to the use of technology, control systems, and machinery to automate manufacturing processes, thereby increasing efficiency, reducing human intervention, and minimizing errors. It has become a vital aspect of modern industries, revolutionizing production by integrating smart technologies like robotics, artificial intelligence (AI), programmable logic controllers (PLCs), and Internet of Things (IoT).

The evolution of industrial automation has transformed traditional labor-intensive industries into highly automated environments, where machines communicate with each other and analyze data to optimize production. This article delves deep into industrial automation systems, exploring their components, benefits, applications, challenges, and future trends.

Understanding Industrial Automation

Industrial automation encompasses a range of technologies that replace manual operations with automatic control systems. The main objective is to enhance productivity, ensure precision, reduce production costs, and improve safety standards.

Automation in industrial settings is broadly classified into the following categories:

- Fixed Automation (Hard Automation): Designed for repetitive tasks such as mass production. It involves specialized equipment tailored for specific operations.

- Programmable Automation: Used in batch production where system parameters can be changed based on requirements.

- Flexible Automation: Allows real-time modifications, making it ideal for varying production schedules.

- Integrated Automation: Combines various automated systems into one network for seamless communication and operation.

Key Components of Industrial Automation Systems

Industrial automation systems consist of several key components working together to automate processes:

- Programmable Logic Controllers (PLCs): The backbone of industrial automation, PLCs are microprocessor-based devices used to control machinery through programmed logic.

- Supervisory Control and Data Acquisition (SCADA): SCADA systems monitor and control industrial processes remotely, providing real-time data visualization and analytics.

- Sensors and Actuators: Sensors collect data from physical surroundings (temperature, pressure, etc.), while actuators execute specific actions based on sensor feedback.

- Human-Machine Interface (HMI): Interfaces that allow operators to interact with automated systems.

- Industrial Robotics: Automated mechanical systems designed to perform complex tasks with precision and consistency.

- Distributed Control Systems (DCS): Used for large-scale industrial operations, DCS integrates multiple controllers for centralized management.

Benefits of Industrial Automation

The adoption of industrial automation systems offers numerous advantages:

- Improved Productivity: Automation enhances production speed, minimizing delays and downtime.

- Higher Precision and Quality: Advanced automated systems maintain consistent product quality.

- Reduced Labor Costs: Automation decreases dependency on manual labor, leading to cost savings.

- Enhanced Safety: Automated systems reduce workplace accidents by handling dangerous tasks.

- Energy Efficiency: Optimized processes ensure minimal resource wastage.

- Real-time Monitoring: Integrated systems provide insights into operations for better decision-making.

- Increased Operational Flexibility: Automation allows industries to adapt swiftly to demand fluctuations.

Applications of Industrial Automation

Industrial automation systems are widely used across multiple sectors:

- Manufacturing: Assembly lines, packaging, and material handling.

- Automotive Industry: Robotic welding, painting, and vehicle assembly.

- Pharmaceuticals: Drug manufacturing, testing, and packaging.

- Oil and Gas: Pipeline monitoring and safety control.

- Food Processing: Sorting, packaging, and quality assurance.

- Electronics: Semiconductor fabrication and circuit board assembly.

Challenges in Industrial Automation

Despite its benefits, industrial automation comes with challenges:

- High Initial Investment: Automation systems require significant financial investment in machinery and infrastructure.

- Maintenance Complexity: Regular servicing is necessary to ensure optimal performance.

- Cybersecurity Risks: Automated systems are susceptible to cyber threats and data breaches.

- Integration Issues: Compatibility concerns arise when incorporating automation into existing industrial frameworks.

- Workforce Displacement: Automation reduces manual labor demand, necessitating retraining programs.

- Dependence on Skilled Workforce: Engineers and technicians must possess specialized knowledge to operate automation systems.

Future Trends in Industrial Automation

The future of industrial automation is shaped by technological advancements such as:

- Industrial Internet of Things (IIoT): Connected devices improve real-time monitoring and optimize operations.

- Digital Twins: Virtual replicas of industrial systems enable simulation and performance optimization.

- 5G & Edge Computing: Faster connectivity improves industrial communication and data processing.

- Autonomous Robotics: Intelligent robots capable of independent decision-making transform industrial operations.

- Sustainable Automation: Green technologies focus on energy-efficient solutions.

Conclusion

Industrial automation systems have revolutionized the global industrial landscape, making operations more efficient, precise, and safe. With continuous technological advancements, the future of industrial automation promises even greater innovation, ensuring sustainable, smart, and autonomous production systems. While challenges persist, industries embracing automation pave the way for a highly optimized and intelligent future.