Introduction

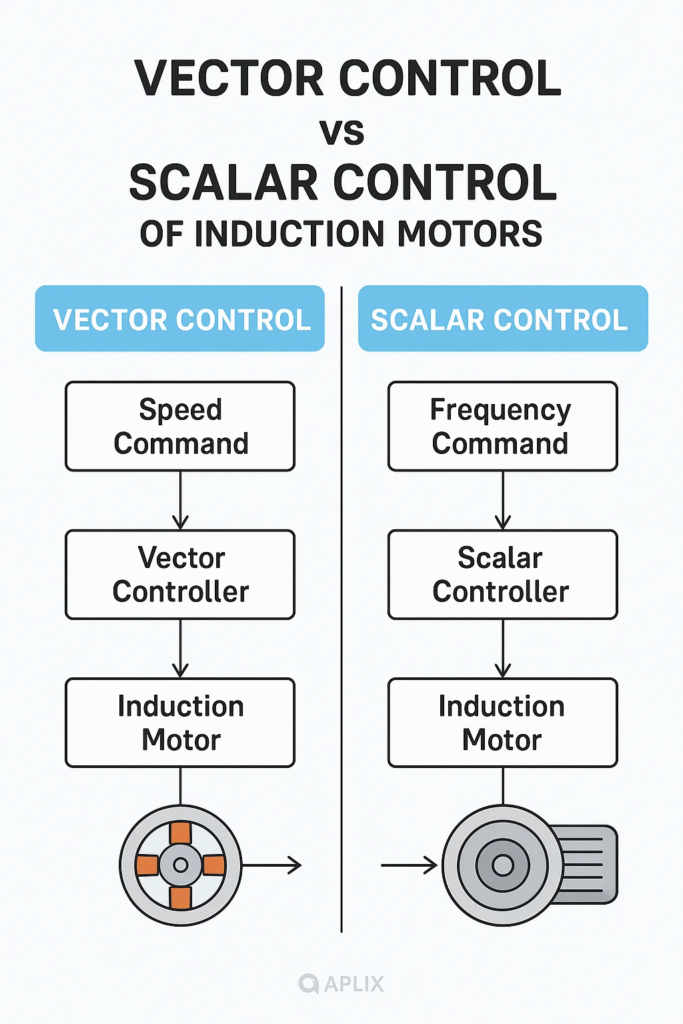

Induction motors are widely used in industrial applications due to their robustness and efficiency. However, controlling their speed and torque effectively requires advanced techniques. Two primary control methods—Scalar Control and Vector Control—are employed to regulate induction motors. While scalar control is simpler and cost-effective, vector control offers superior dynamic performance and precision. Understanding the differences between these methods is crucial for selecting the appropriate control strategy.

Scalar Control (V/f Control)

Scalar control, also known as Volts per Hertz (V/f) control, regulates the motor by maintaining a constant voltage-to-frequency ratio.

Principle

- The motor’s voltage and frequency are adjusted proportionally to control speed.

- No consideration is given to the phase relationship between voltage and current.

Advantages

- Simple implementation.

- Cost-effective.

- Suitable for applications where precise torque control is not required.

Disadvantages

- Limited dynamic performance.

- Poor torque control at low speeds.

- Inefficient for high-performance applications.

Vector Control (Field-Oriented Control – FOC)

Vector control, also known as Field-Oriented Control (FOC), manages both the magnitude and phase of stator currents to achieve precise motor control.

Principle

- Uses mathematical transformations (Clarke and Park transformations) to convert three-phase currents into a rotating reference frame.

- Separates torque and flux components for independent control.

Advantages

- High dynamic performance.

- Precise torque and speed control, even at low speeds.

- Ideal for high-performance applications such as robotics and electric vehicles.

Disadvantages

- More complex to implement.

- Requires additional sensors and computational resources.

- Higher cost due to complexity.

Conclusion

Scalar control is a straightforward and cost-effective method for controlling induction motors, making it suitable for applications where precision is not critical. However, for demanding applications requiring accurate torque and speed control, vector control is the preferred choice. As industries move toward automation and efficiency, vector control is increasingly adopted for its superior performance and adaptability.